The automotive sector employs millions of people worldwide, making it one of the most important industrial sectors. Many of the jobs are not created by the major automakers themselves, but by the numerous companies who supply them.

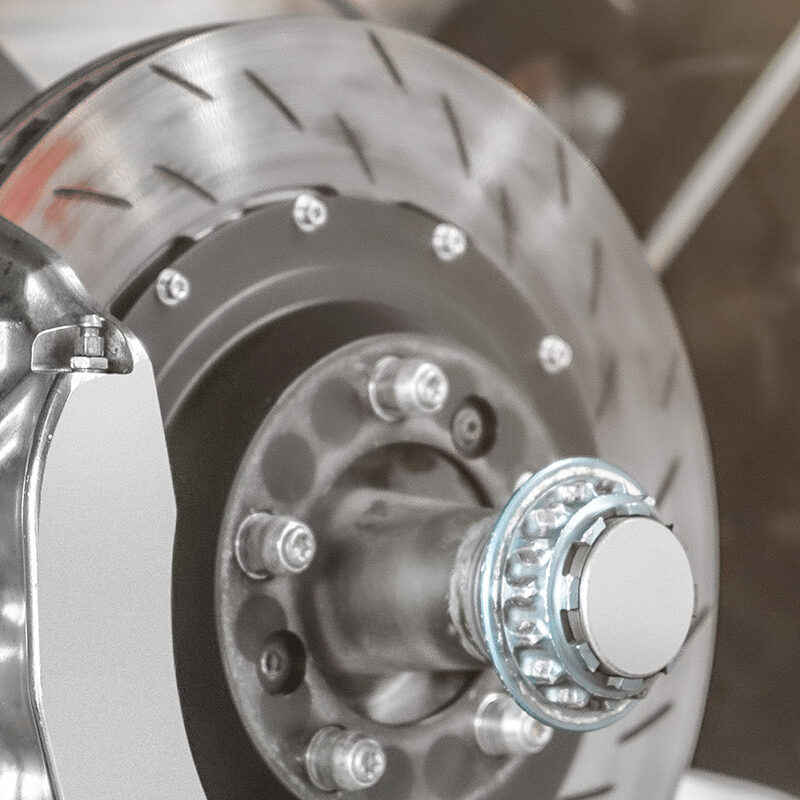

The primary technical challenge faced by the automotive industry relates to growing demands from both policymakers and the public for low-emission drive systems. To meet this challenge, the sector is taking a two-pronged approach. The first part of the strategy involves lightweight construction techniques, which lowers the weight of vehicles in order to reduce CO((2)) emissions. Companies are also seeking ways to shave weight off of powertrain components, transmissions, engine cases, brake discs, and other parts. The second involves new drive concepts, with the primary focus on e-mobility, which has a major impact on the overall drive concept for the vehicle. Along with developing electric vehicles, the car industry is now preparing for other challenges such as hydrogen and synthetic fuels.

Despite the many technical challenges and thanks to the innovations being made, the automotive sector will continue to focus on meeting the highest standards in terms of quality, safety, and precision. Safety-related components like powertrain parts, transmissions, engine cases, and brake discs must meet the most stringent requirements when it comes to precision. For the metal machining industry, this means adapting to changing market demands and requirements imposed by policymakers. In addition to quality parameters such as surface finish, productivity is another key factor for the automotive industry. State-of-the-art manufacturing techniques allow automotive suppliers to produce more components in less time while being able to meet their delivery obligations at all times.

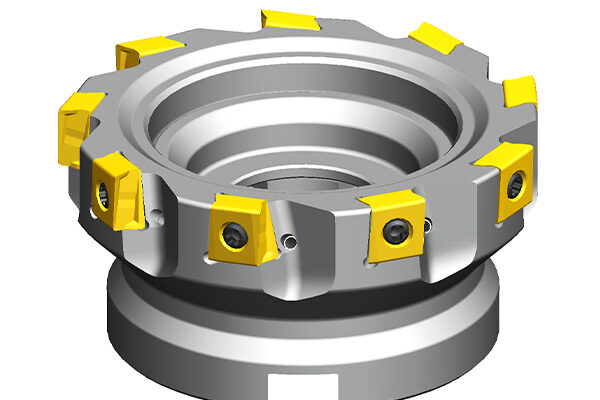

Spheroidal-graphite cast iron (EN-JS-1060), gray cast iron (EN-GJL-250), powder metallurgical steel (PM60), aluminum alloys (AlSi9Mg), and group P materials (16MnCr5/100Cr6) are some of the materials machined in the automotive industry. ZCC-CT understands the specific challenges relating to each of these materials and offers the automotive industry cutting tools that meet their exact needs. Our line of products includes the YZB and YCB series of turning inserts, which are ideal for machining ISO H materials. The solid carbide drills from the GD series as well as the EMP09 and FMD02 indexable insert cutters are also highly popular especially with customers in the automotive industry.