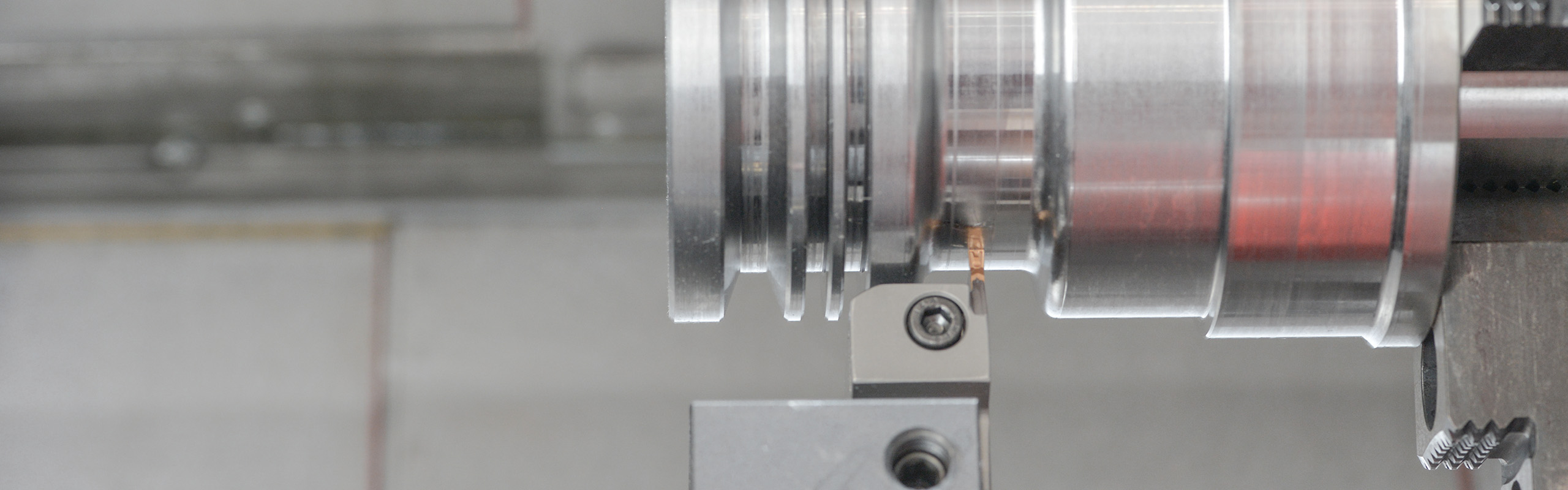

Parting off and grooving is a key step in the manufacture of high-quality components. The process can be broken down into several sub-steps which include parting off, grooving and turning. As with general turning operations, the rotation of the workpiece generates the cutting motion. The tool movement (f((n))) is in the radial and axial feed direction.

Controlled chip removal, protrusion-free parting off and tool breakage are some of the many challenges associated with this manufacturing process. Process stability and reliability are particularly important during parting off, since this is the final machining operation in the cutting process. It is critical that you choose the right inserts and manufacturing strategy in order to get the desired results.

ZCC Cutting Tools helps you develop a tooling solution and machining strategy that meets your specific needs. Do you need help with grooving and parting off applications? Then contact us. We’re there to help.