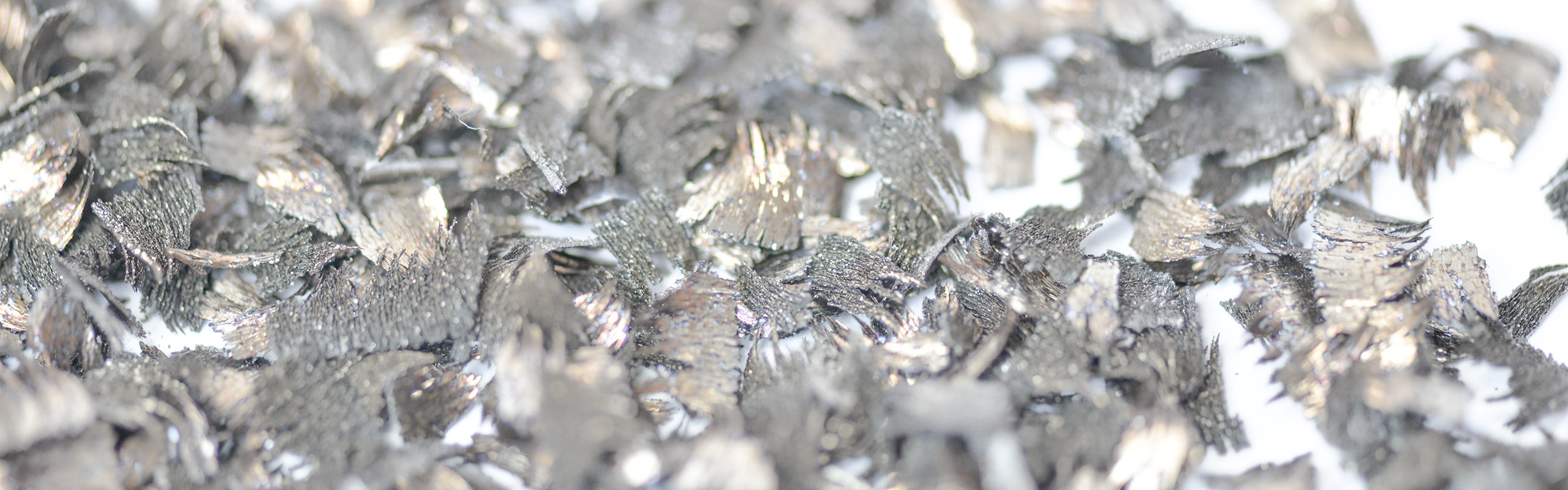

Cast iron contains more than 2 percent carbon and, in many cases, silicon, chromium, or nickel to improve flow properties. The finished components are highly corrosion resistant, but also brittle. This is why further machining is only possible by stock removal, while mechanical working is generally not viable. The machinability of the material varies from grade to grade. Process reliability plays an important role during machining because seasonal fluctuations in batch quality may also occur with this cast material.

Here are a few of the main cast iron materials that are also difficult to machine:

- EN-JS-1060: This is a low-cost cast iron with nodular graphite in the material matrix (material number 0.7060). It is also known as GGG60 and has excellent mechanical properties. EN-JS-1060 is therefore suitable for use in automotive (engines, crankshafts/camshafts), rail (wheels), and general engineering (pump cases) applications. Some of the challenges encountered when machining the material include high tool wear as well as blowholes and sand residue from the mold that have the potential to damage the cutting tool.

- EN-GJL-250: With this material (material number 0.6025), the carbon is in the form of flake graphite. It is also known as GG25. It conducts heat well, is rigid, absorbs vibrations, and is highly resistant to pressure. In the automotive and general engineering field, it is used in the production of vibration-absorbing machine bases, steam turbine cases, and gearboxes. When machining GG25, it is important to also monitor for increased tool wear due to sand residue from the mold.

- EN-GJMW-350-04: The material is also called EN-JM1010 and white malleable cast iron. Extremely thin-walled components can be cast from EN-GJMW-350-04. In addition to its superior galvanizing properties, the material is tough and corrosion resistant, absorbs vibrations, and is easy to machine. In the automotive sector, it is used in the production of steering, chassis, and transmission parts.

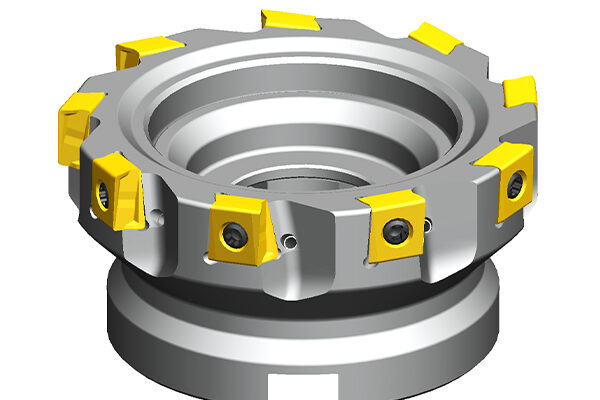

When machining cast iron components, the specific properties of the material group must be taken into account in each case. For example, there are differences in how cast iron with flake graphite and cast iron with nodular graphite are machined. No matter what type of cast iron material you are looking to machine, ZCC-CT is able to offer you the machining tool you need from its wide assortment of products.