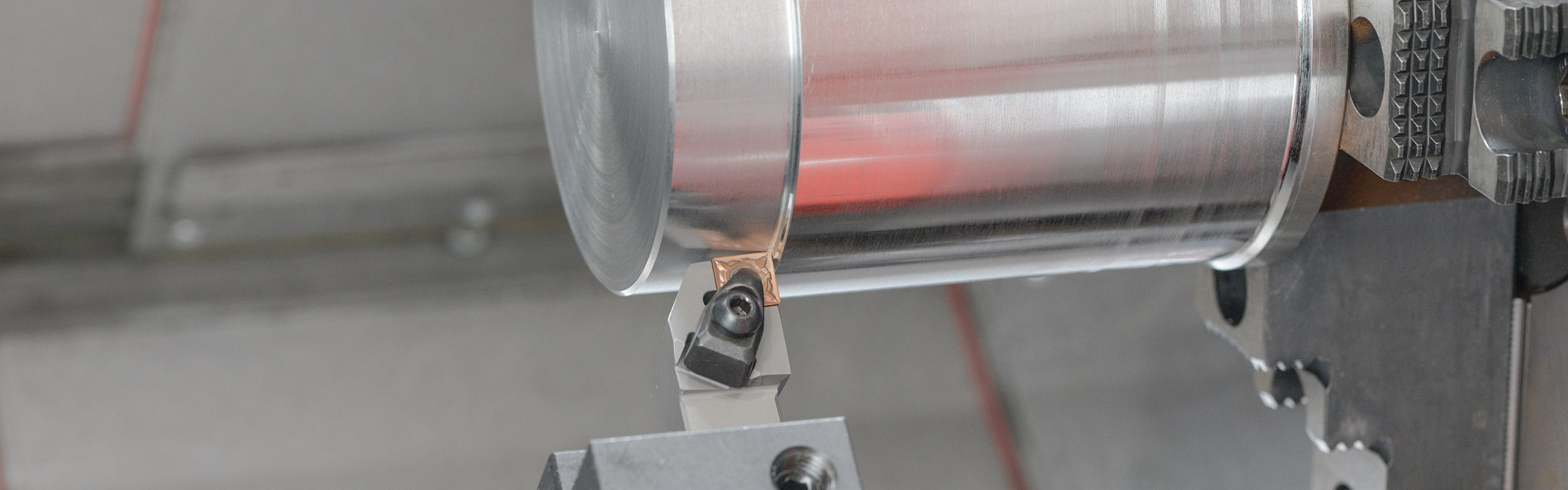

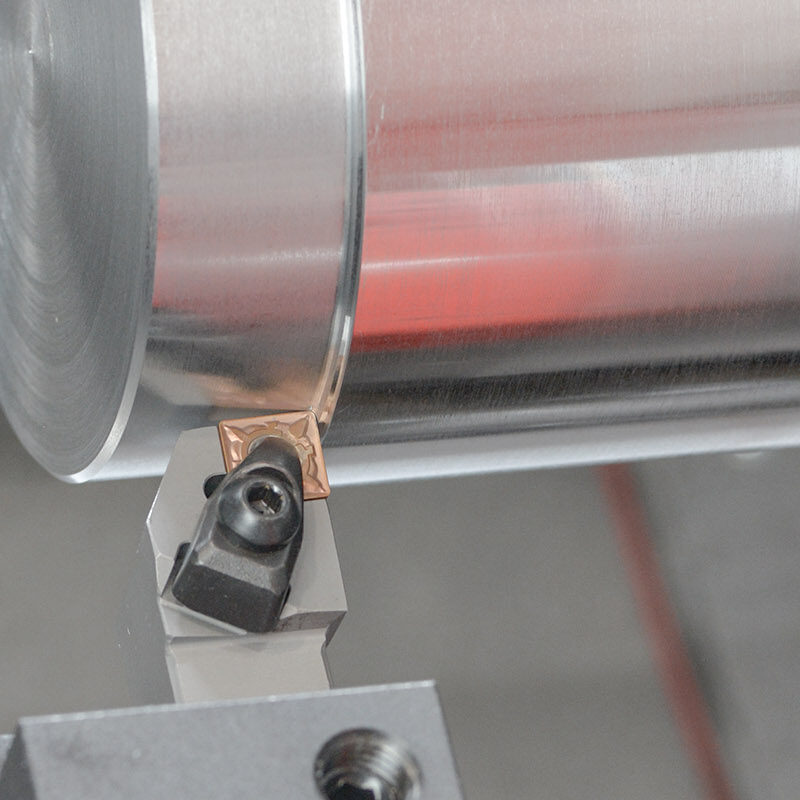

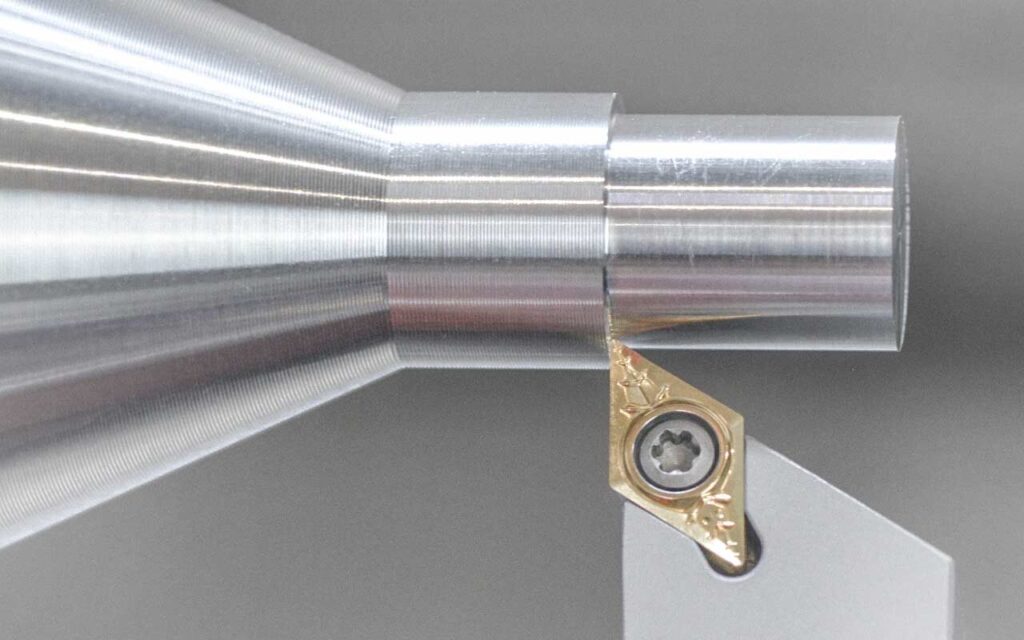

General turning is a key machining process in the metal-working industry. In this operation, the insert creates a cylindrical form using a defined geometric cutting edge. The rotation of the workpiece produces a cutting motion, while the turning tool carries out the radial (a((p))) and axial feed motion (f). The turning operation can be broken down into several sub-steps, which include face turning, longitudinal turning and profiling.

The component properties, material and machining conditions are critical to the success of the machining operation. These factors have a major impact on the process, requiring special attention during the planning phase. The main challenge in any turning operation is how to achieve a long, consistent tool life with optimum chip removal. The first thing the user needs to do is ensure that chips are optimally removed from the workpiece and break off.

ZCC Cutting Tools offers the accompanying chip breaker for every application. Our experts select a suitable grade based on the customer’s requirements and component properties. Do you need help with your general turning applications? Then contact us. We’re there to help.