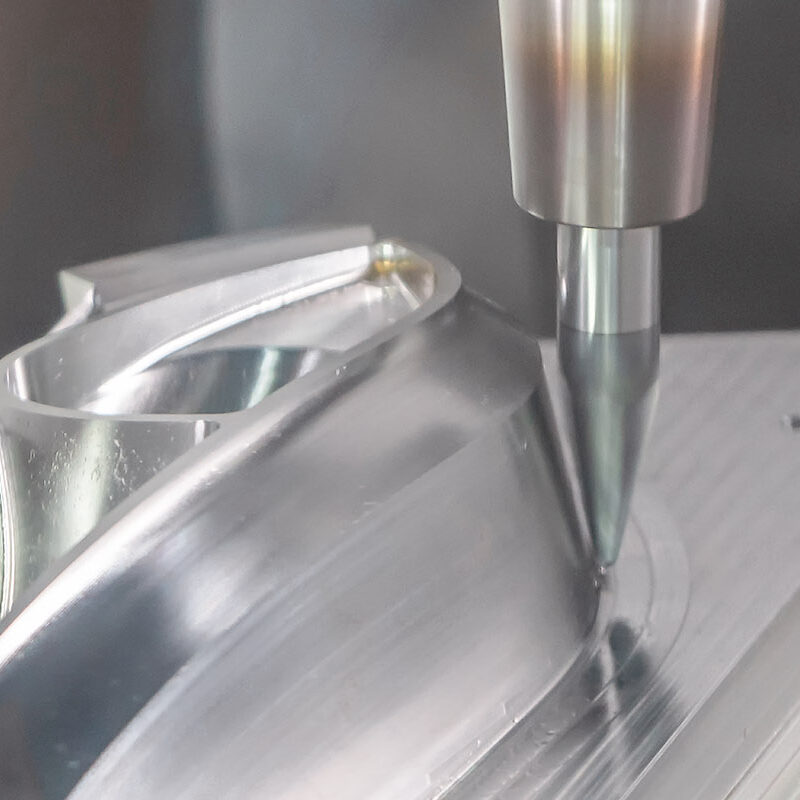

Copy milling is more commonly known as free-form milling. As the name would suggest, a copy is made of the object being milling. The cutter generates complex geometric (free) forms which are typically non-angular. The machining technique is commonly used in tool and mould-making industry.

There are a number of challenges that come with copy milling, including the large volume of metal removed by cutting (Q) during roughing and how to achieve a high surface quality during finishing. The tool overhang in copy milling operations is generally greater than in other applications, which is why low cutting forces are an important criterion. Toric tools and high-feed mills are suitable for effective roughing and pre-finishing in most cases. To produce the final finished surface, indexable and solid carbide ball nose cutters are primarily used in order to avoid contour distortion.

ZCC Cutting Tools offers both indexable and solid carbide tools that make copy milling easier for you. Do you need help with your copy milling applications? Then contact us. We’re there to help.