Radical changes have been taking place in the engineering sector over the past few years. Industry 4.0, digitalization, and big data are code words for the cross-sector networking of machines made possible through the interaction between electronic and mechanical components. The digitalization and networking of machines will help facilitate major improvements in industrial productivity in the years to come.

Tempered, tool, and wear-resistant steels, wrought aluminum alloys, and cast materials have been the traditional materials used in the mechanical engineering field. When it comes to machining these materials, it is necessary to consider the specific challenges presented by each one.

In the case of structural steel (unalloyed ISO P steel/S235), these include poor chip breaking, impurities in the material, and the risk of built-up edges. Conversely, high tensile strength, excessive wear, and significant heat build-up in the cutting zone make it difficult to machine quenched and tempered steel (low-alloy ISO P steel/42CrMo4+QT). In the case of tool steel (high-alloy ISO P steel/X155CrVMo12-1), significant fluctuations in quality between batches, process reliability, and the high cutting forces required to machine them are all issues to consider. Lastly, extreme hardness and heavy wear due to heat build-up in the cutting zone make it a challenge to machine wear-resistant steel (high-alloy ISO P steel/Hardox 500).

Machine manufacturers are faced with constant pressure to keep costs down. Users expect to receive a universal product for as many materials and applications as possible.

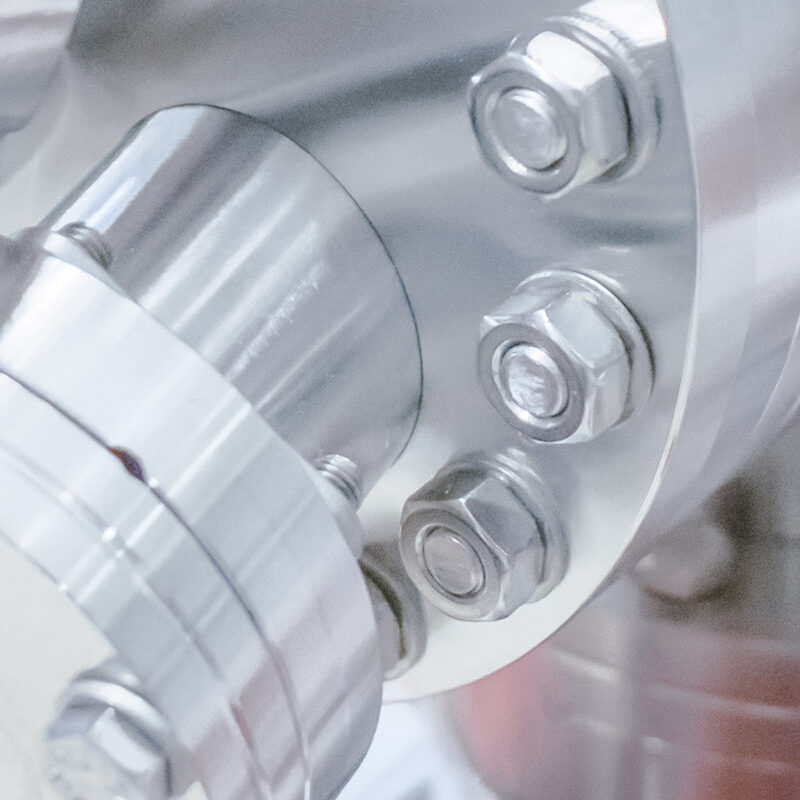

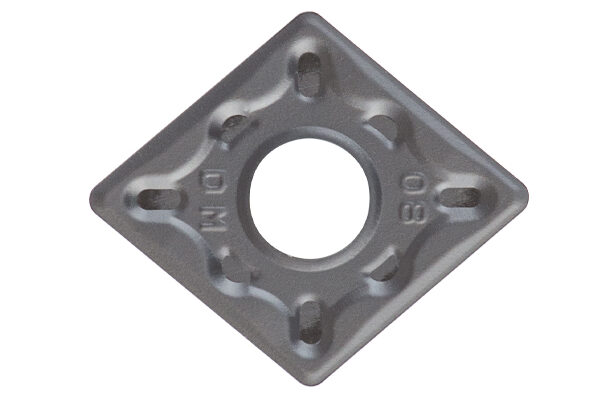

To meet this demand, ZCC-CT offers machine manufacturers a broad assortment of high-quality tools for machining a wide variety of materials. These include the SU series of solid carbide drills, which are ideal for machining a range of materials thanks to their patented sickle design. The YBC series of turning inserts is likewise the right choice when it comes to the precision machining of ISO P materials. Along with that, the ZSD indexable insert drill is amazingly flexible, making it well suited for a wide range of applications. ZCC-CT is your partner of choice for precision tools for mechanical engineering applications.