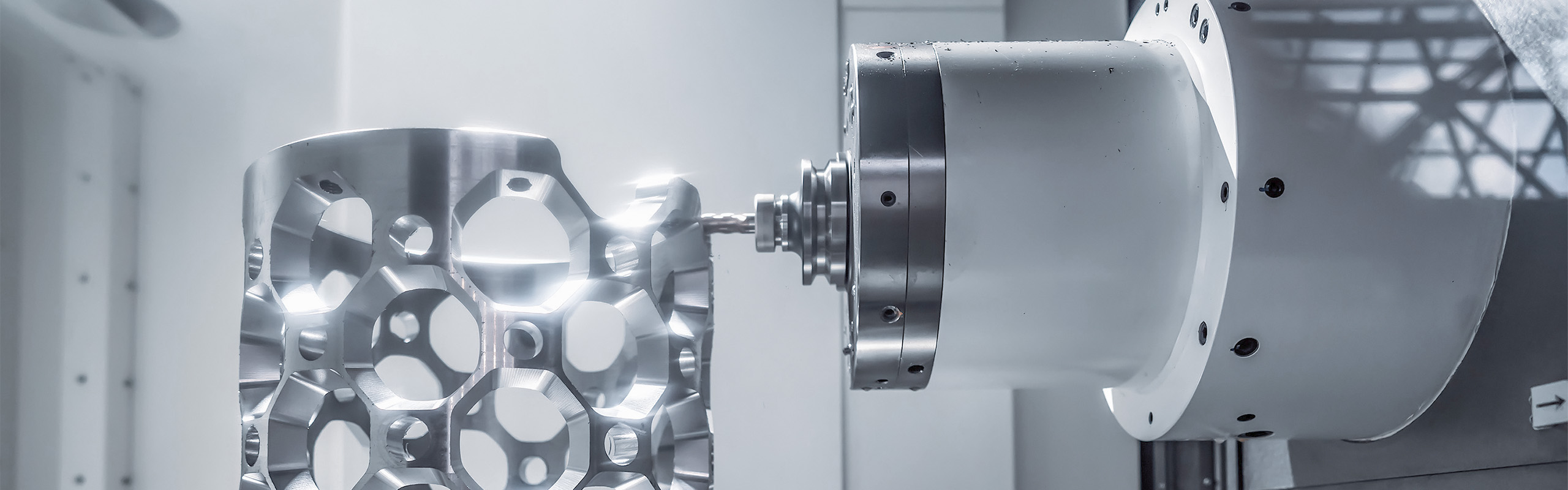

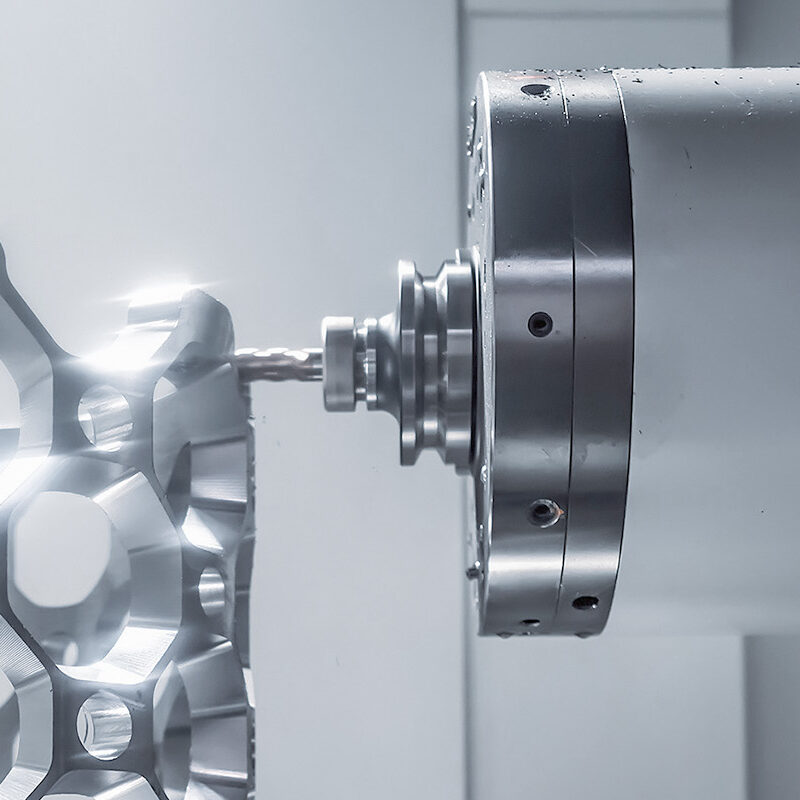

Shoulder milling is a basic milling application in which a tool simultaneously creates a plane and shoulder surface. Square shoulder mills have traditionally had a cutting edge angle of 90°. Having the exact right angle is important to avoid offsets between the individual milling paths. Indexable and solid carbide tools are both suitable for shoulder milling. Each tool has its own advantages.

Machine performance, component geometry and surface requirements are just a few of the main criteria when it comes to choosing the right tool. Because the milling bodies can be reused, indexable milling cutters are less expensive, also in terms of lower follow-up costs. Solid carbide milling cutters are the ideal choice for applications that require greater precision and higher surface quality.

ZCC Cutting Tools offers a wide array of indexable and solid carbide cutters designed to optimise your milling processes. Do you need help with your shoulder milling applications? Then contact us. We’re there to help.