Thanks to our wide range of indexable mills, we are able to offer you a large number of solutions for your milling operation. Whether it’s face, shoulder, or high-feed milling, we have the right tool for your application.

Indexable Mills

Recommendations for Indexable Mills

Overview of Indexable Mills

PG8020 CVD (PANGU)

M

S

Aerospace

Energy Management

General Engineering

PG8030 CVD (PANGU)

M

S

Aerospace

Energy Management

General Engineering

EMP08

K

M

P

S

Aerospace

Energy Management

General Engineering

EMP10

K

M

P

Automotive

Die and Mold Making

Energy Management

General Engineering

XMR13

K

M

P

Automotive

Die and Mold Making

Energy Management

General Engineering

XMR12

M

P

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

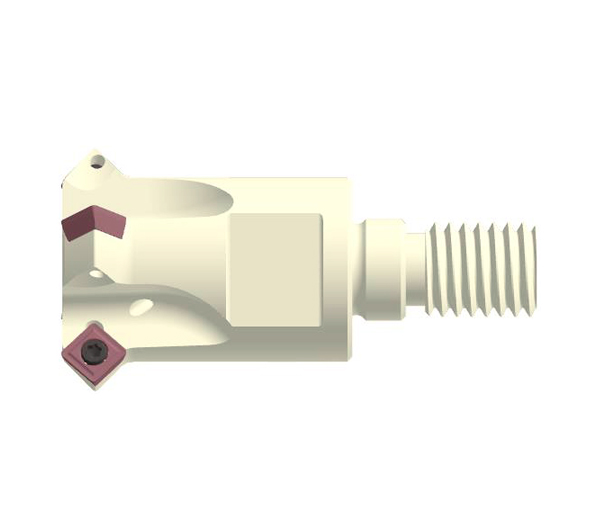

QCH ENMX (M)

M

P

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

SMP09

M

P

Die and Mold Making

Energy Management

General Engineering

FMR11

K

M

P

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

FME17

K

M

P

Automotive

Die and Mold Making

Energy Management

General Engineering

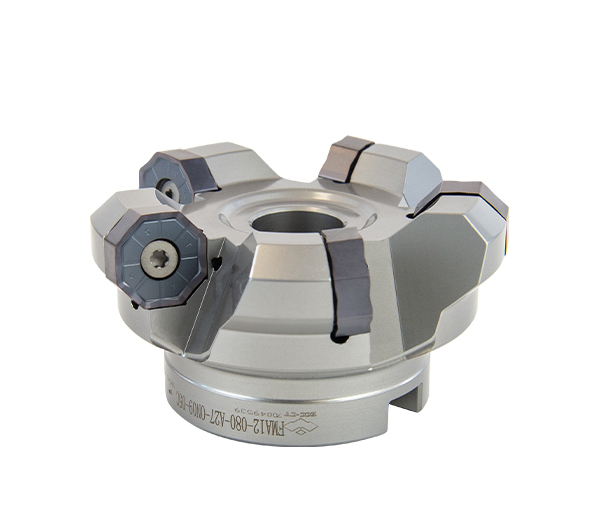

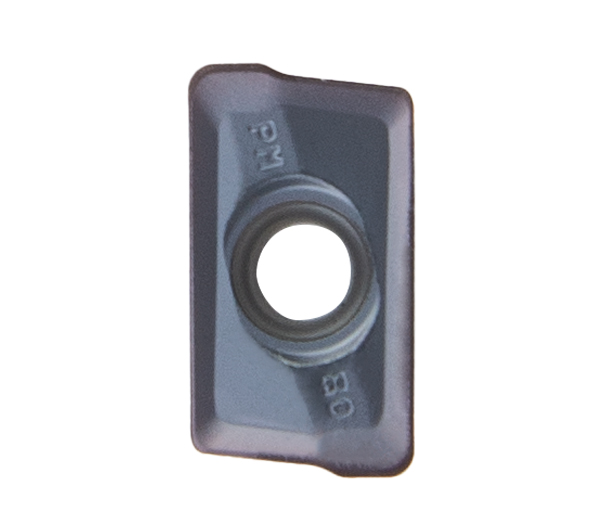

FMA12

K

M

P

Automotive

Die and Mold Making

General Engineering

Medical Technology

EMP05

K

M

P

Die and Mold Making

Energy Management

General Engineering

YBG205H PVD

H

M

P

Automotive

Die and Mold Making

Energy Management

General Engineering

EMP14

N

X

Aerospace

FMR06

K

M

P

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

FMP06

K

M

P

Automotive

Die and Mold Making

Energy Management

General Engineering

FMP17

K

M

P

Automotive

Die and Mold Making

Energy Management

General Engineering

FMA17

K

M

P

Automotive

Die and Mold Making

Energy Management

General Engineering

FMA11

K

M

P

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Medical Technology

FMA01

K

M

N

P

Automotive

Die and Mold Making

Energy Management

General Engineering

Medical Technology

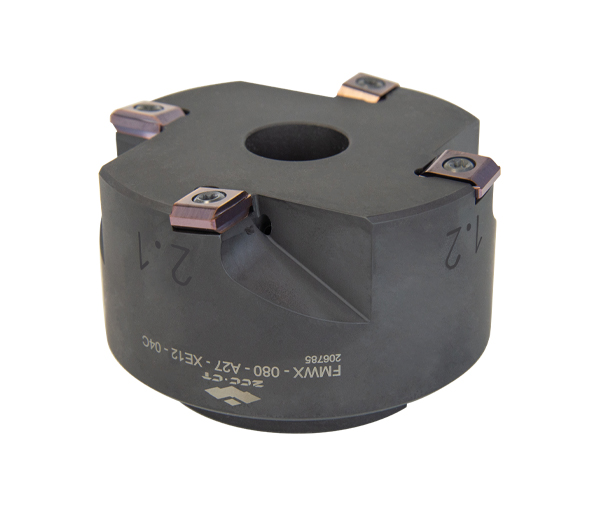

FMWX

K

P

Automotive

Die and Mold Making

Energy Management

General Engineering

FMA04 ODHT

K

M

N

P

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Medical Technology

FMD02 PNEG

K

P

Automotive

General Engineering

FMD02 HNEX

K

P

Automotive

General Engineering

FMD03

K

M

P

Energy Management

General Engineering

BMR03

K

P

Die and Mold Making

General Engineering

FMR01/02

K

M

P

S

Aerospace

Die and Mold Making

General Engineering

Medical Technology

FMR03/04

K

M

N

P

Die and Mold Making

General Engineering

Medical Technology

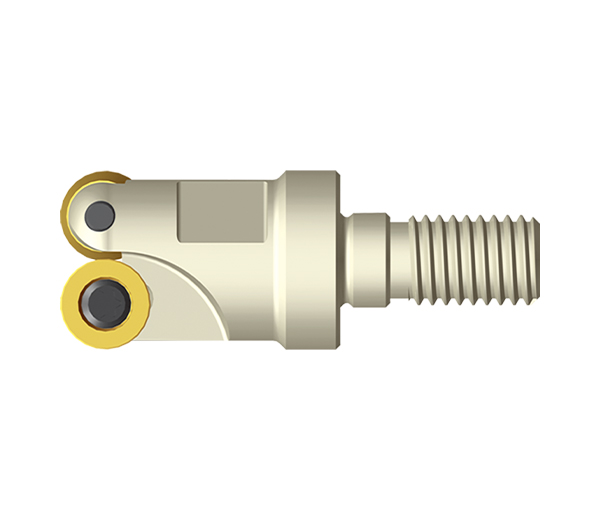

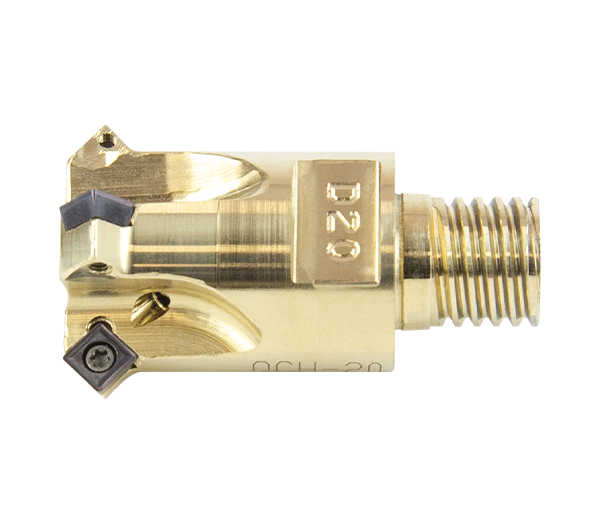

QCH RDKW (M)

K

M

N

P

Die and Mold Making

General Engineering

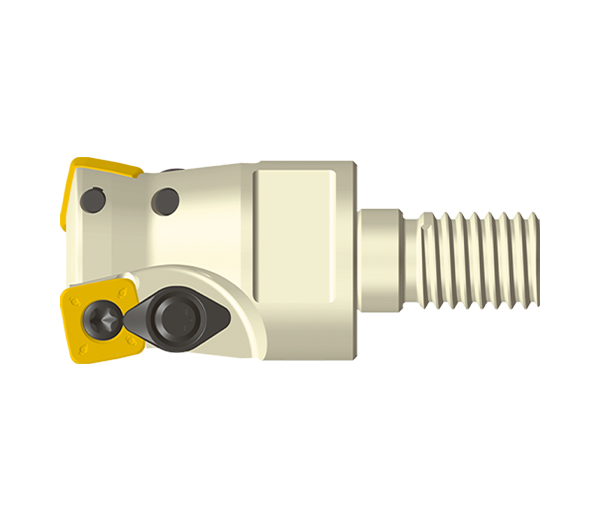

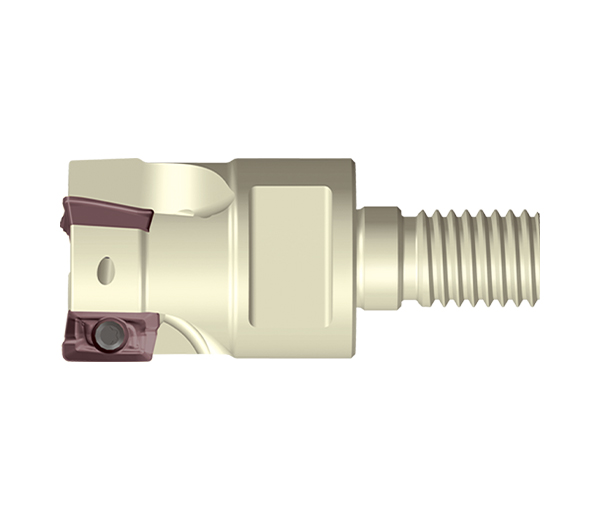

QCH SDMT (M)

K

M

P

S

Die and Mold Making

General Engineering

QCH SDMT (Q)

K

M

P

S

Die and Mold Making

General Engineering

XMR01

K

M

P

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Rail Technology

QCH SPGT (M)

K

M

N

P

S

Die and Mold Making

General Engineering

QCH SPGT (Q)

K

M

N

P

S

Die and Mold Making

General Engineering

QCH APKT (M)

K

M

N

P

S

Die and Mold Making

General Engineering

QCH APKT (Q)

K

M

N

P

S

Aerospace

Die and Mold Making

General Engineering

EMP01/02

K

M

N

P

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Rail Technology

EMP13

K

M

N

P

Automotive

Energy Management

General Engineering

Medical Technology

EMP09

K

M

P

Automotive

Energy Management

General Engineering

QCH LNKT (M)

K

M

P

Automotive

Energy Management

General Engineering

All

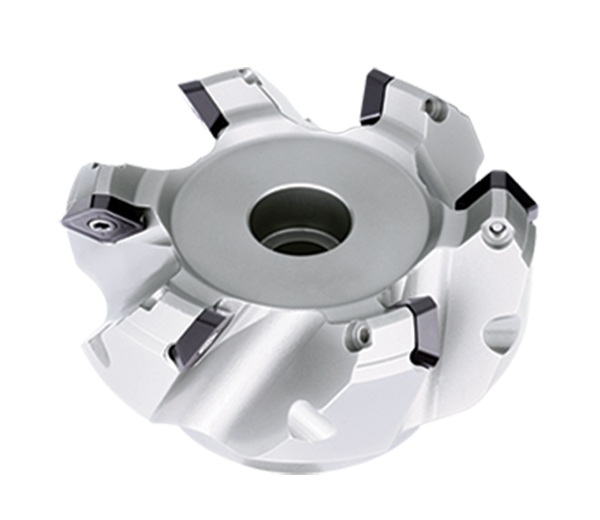

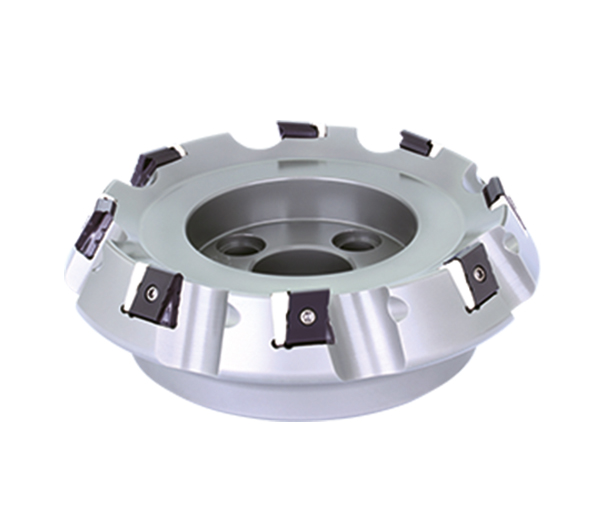

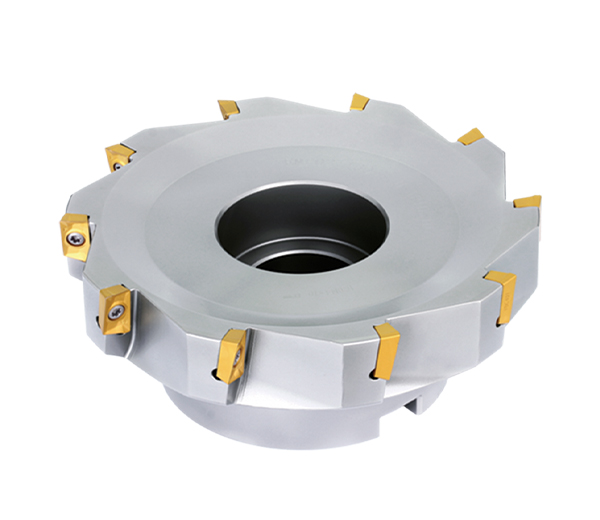

Face Mills

Square Shoulder Mills

High-Feed Mills

Copy Mills

Chamfer Mills

contact

ZCC Cutting Tools Europe