There are a number of challenges we face when it comes to helping you maximize your productivity. These include issues like how to achieve reliable chip removal, a consistent tool life and short machining times regardless of the material you’re using. We’ll show you selected products that provide real benefits for your company and production operations. You can find our full line of products in our general catalog.

Turning Tools

Recommendations for Turning Inserts

Overview of Turning Inserts

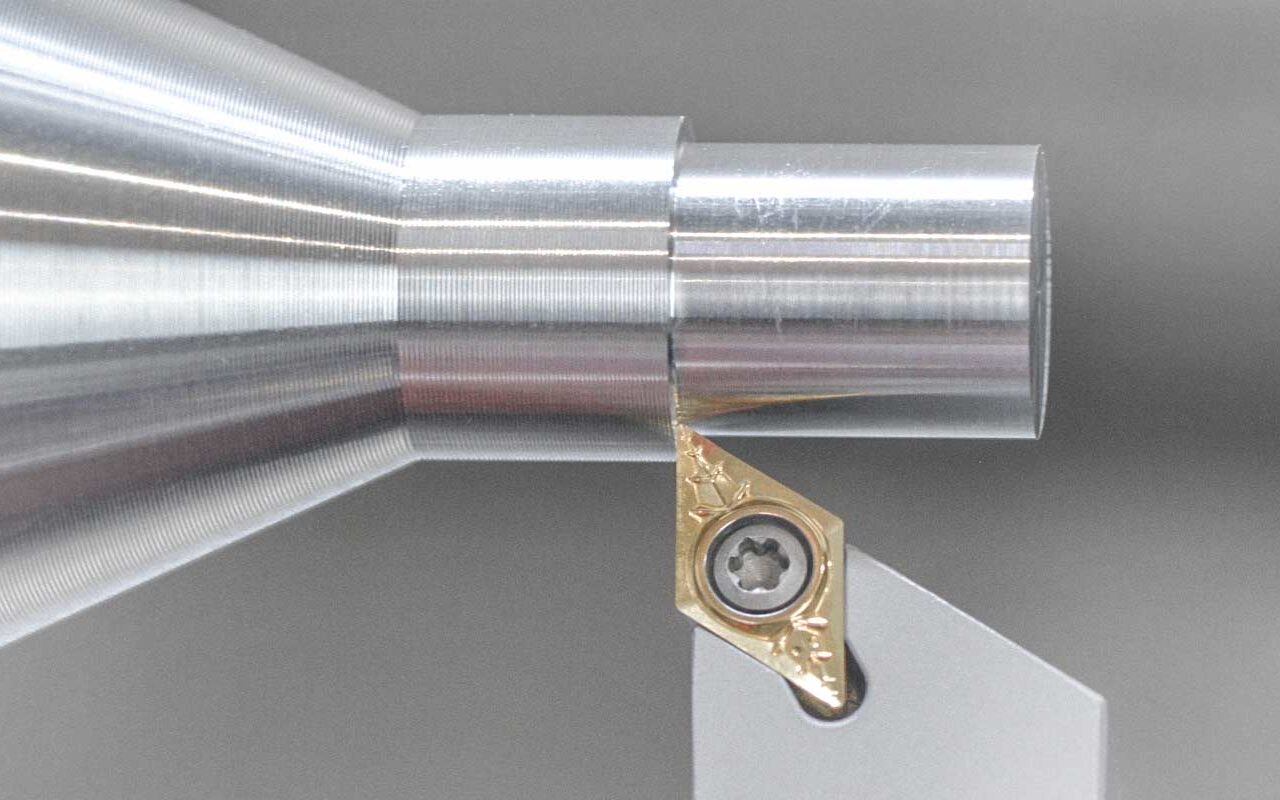

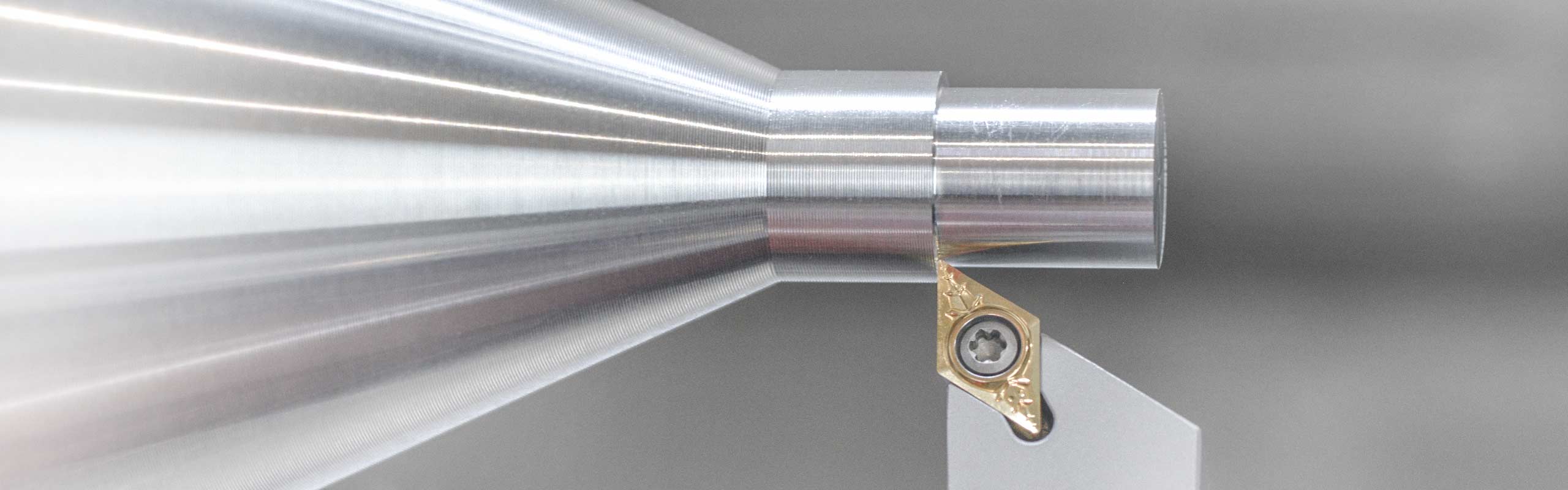

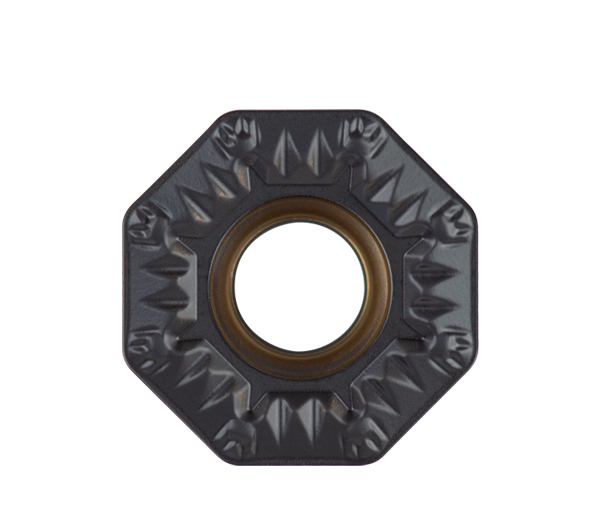

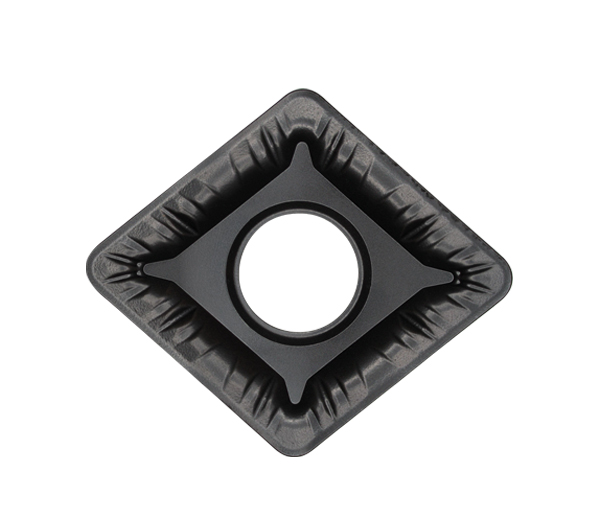

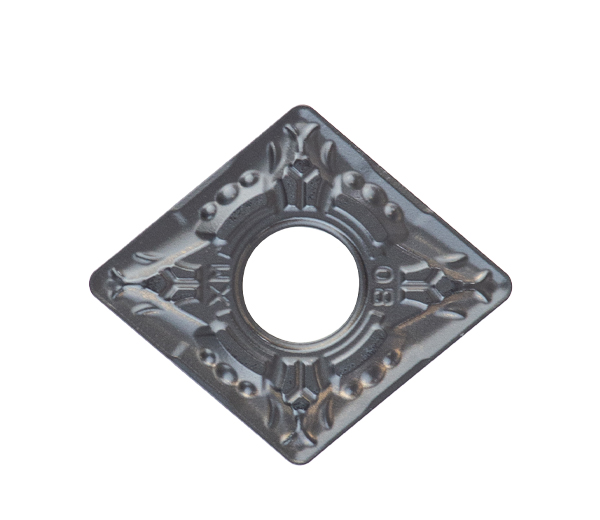

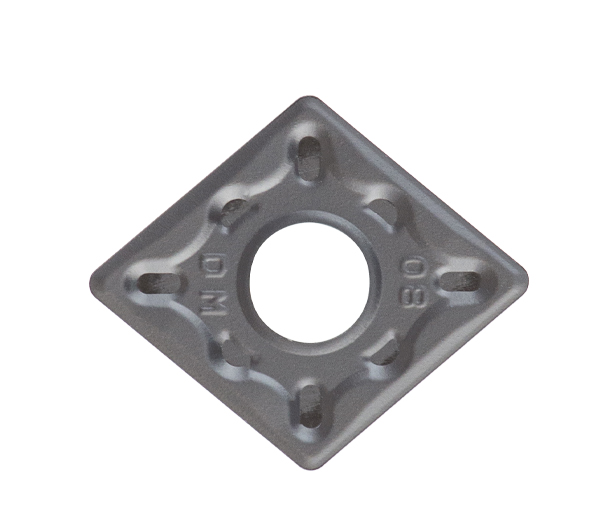

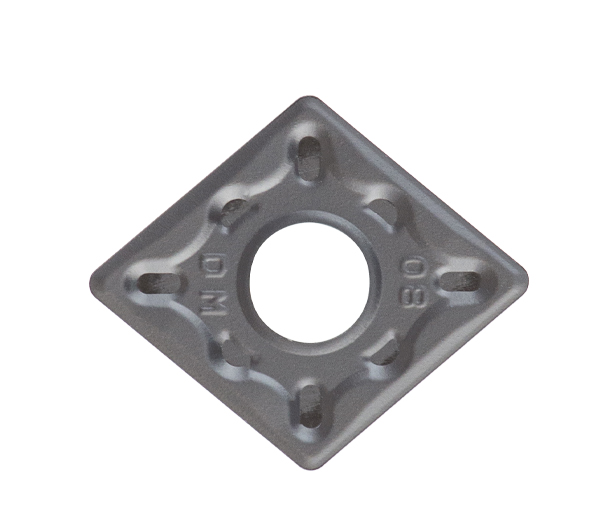

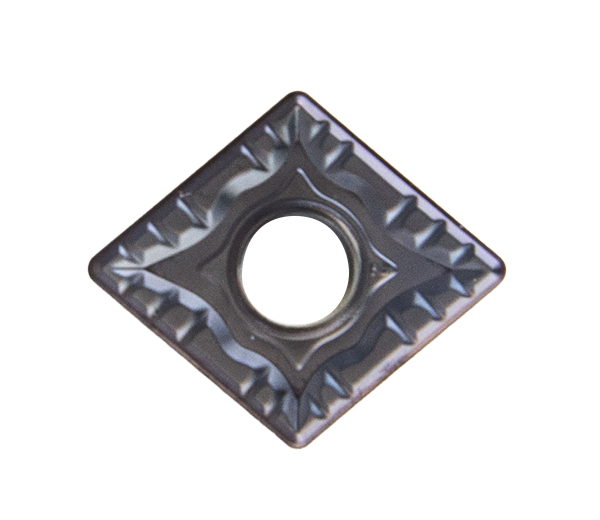

ONMX-XH

M

P

Automotive

Energy Management

General Engineering

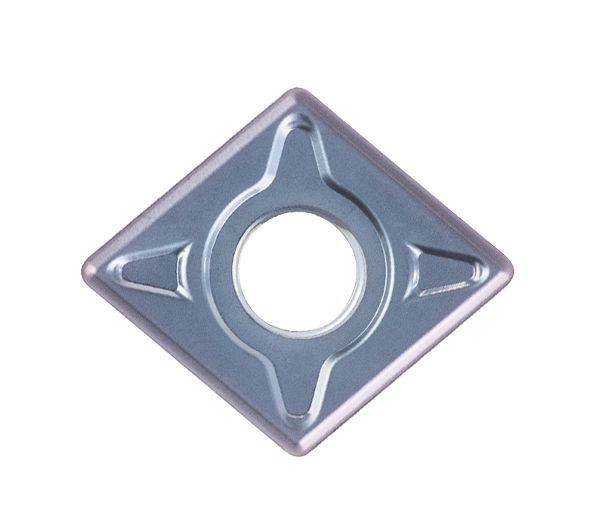

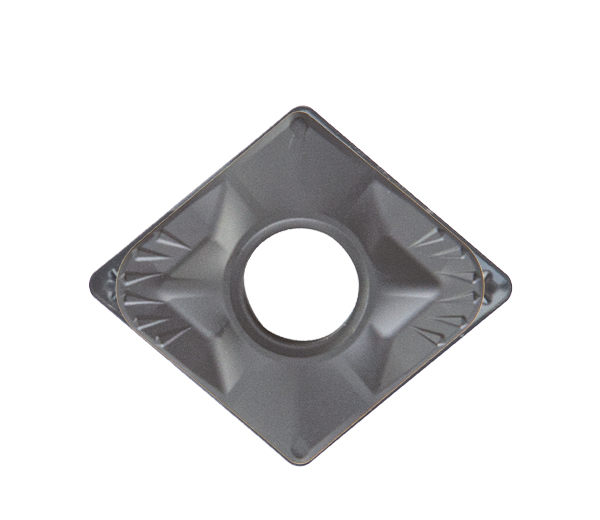

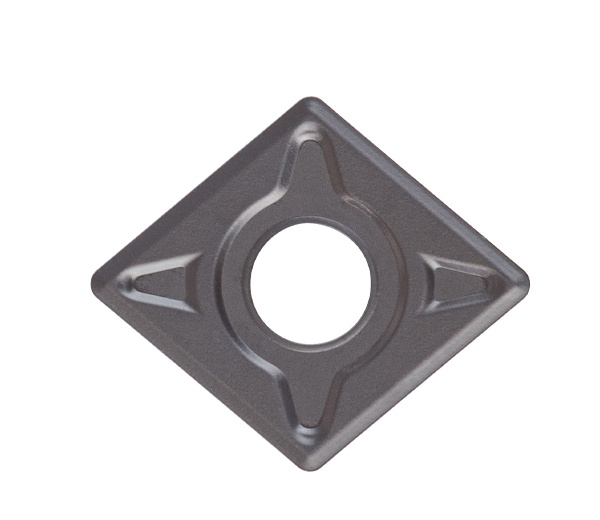

PNMX-XH

M

P

Automotive

Energy Management

General Engineering

-XLR chip breaker

P

Automotive

Energy Management

General Engineering

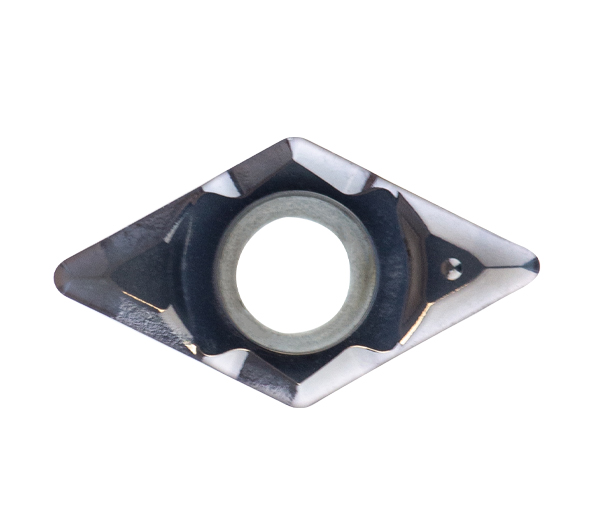

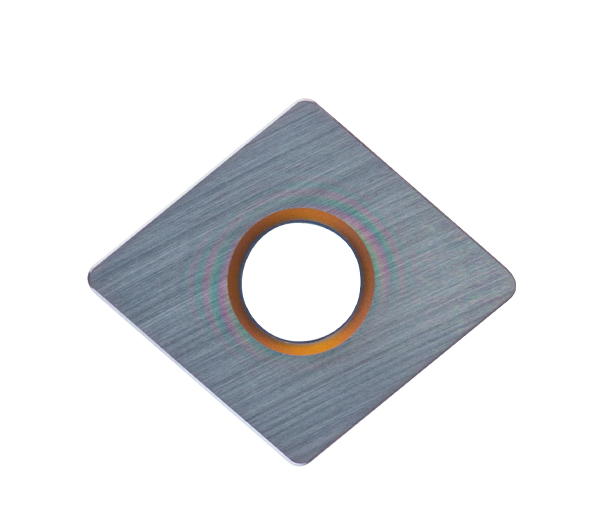

CSX1000 grade

S

Aerospace

Die and Mold Making

Energy Management

General Engineering

-MU chip breaker

K

M

P

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

YBG205H PVD

M

P

Automotive

Die and Mold Making

Energy Management

General Engineering

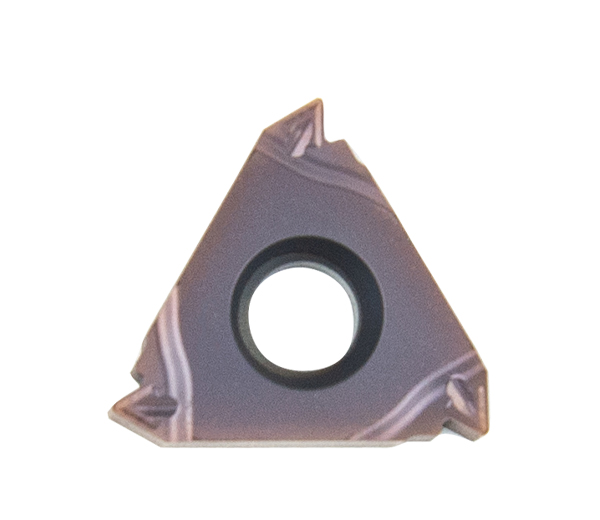

zType threading inserts

M

P

Automotive

General Engineering

Medical Technology

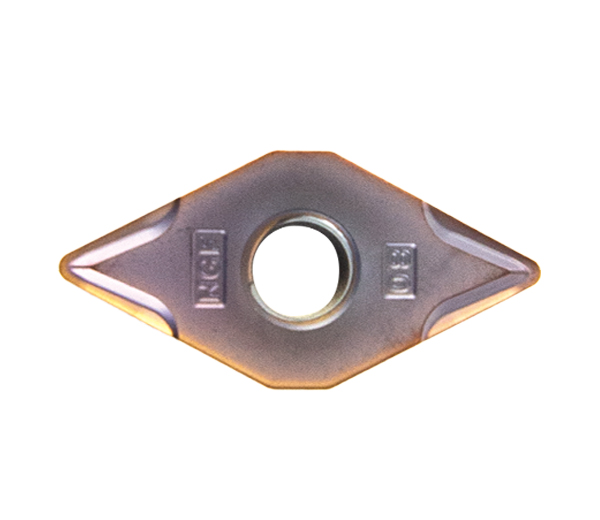

-XMH chip breaker

P

Automotive

Energy Management

General Engineering

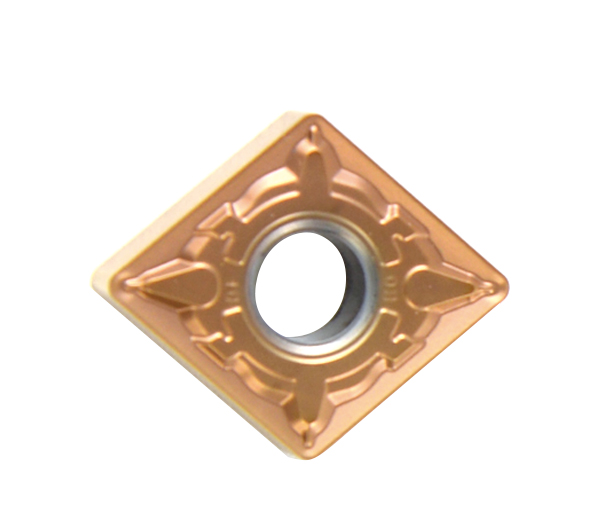

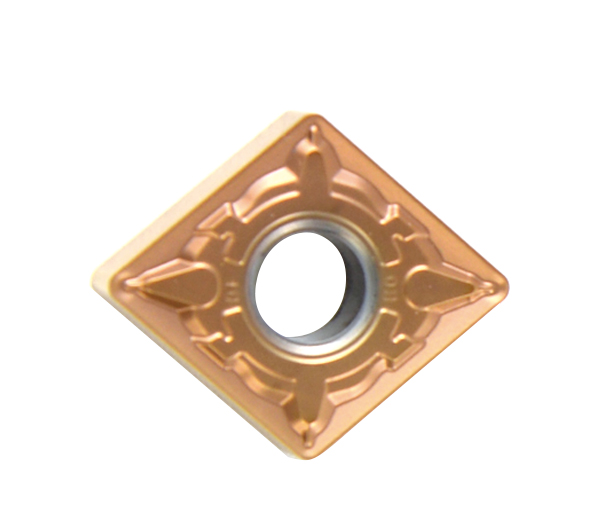

YBC103 & YBC203 CVD

P

Automotive

Energy Management

General Engineering

-XF chip breaker

P

Automotive

Energy Management

General Engineering

-XM Chip breaker

P

Automotive

Energy Management

General Engineering

CNMM-RH Railway wheel re-turning

P

Rail Technology

YB9320 PVD

M

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Medical Technology

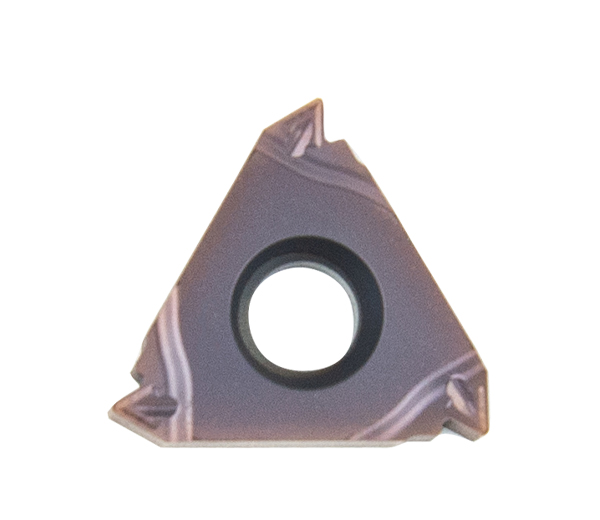

Threading inserts

M

P

Automotive

General Engineering

Medical Technology

CNMM-RF Railway wheel re-turning

P

Rail Technology

LNUX-RH Railway wheel re-turning

P

Rail Technology

LNUX-RF Railway wheel re-turning

P

Rail Technology

YBG Series PVD

M

S

Aerospace

Energy Management

Medical Technology

YBD Series CVD

K

Automotive

Die and Mold Making

Energy Management

General Engineering

Rail Technology

YBM Series CVD

M

Aerospace

Energy Management

General Engineering

Medical Technology

YN Series Cermet

P

Automotive

General Engineering

Medical Technology

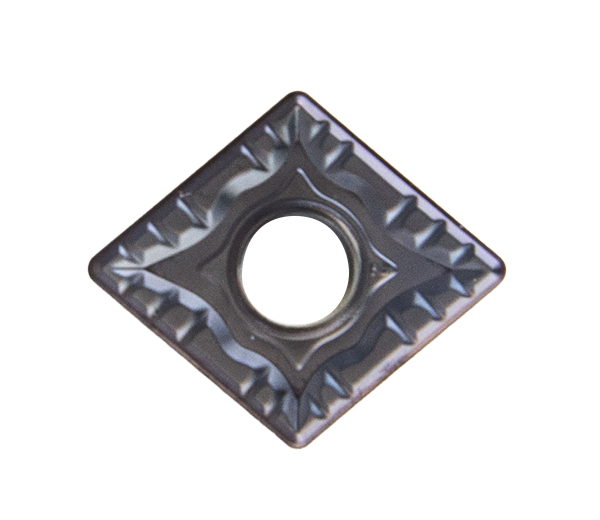

YBC Series CVD

P

Automotive

Die and Mold Making

General Engineering

Rail Technology

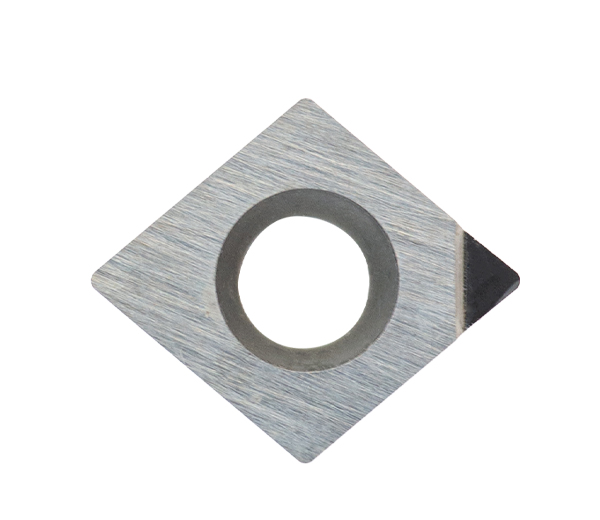

YCD421 PCD

N

X

Aerospace

Automotive

Medical Technology

-LC YBG101

N

Aerospace

Automotive

Energy Management

Medical Technology

-LH YBG102

N

Aerospace

Automotive

Energy Management

Medical Technology

-MM Chip breaker

K

M

P

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Medical Technology

YB9320 PVD

M

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Medical Technology

CW Series Ceramic

S

Aerospace

Automotive

Energy Management

Medical Technology

-SNR Chip breaker

S

Aerospace

Energy Management

Medical Technology

YBS Series PVD

S

Aerospace

Energy Management

Medical Technology

CA1000 / CM1000 Ceramic

H

Automotive

General Engineering

YCB Series CBN

H

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

CN1000 Ceramic

K

Automotive

General Engineering

YZB223 CBN

K

Automotive

General Engineering

-TC YB7315

K

Automotive

General Engineering

Rail Technology

-AHF / -ADF Chip breaker

M

P

Aerospace

Automotive

Energy Management

General Engineering

Medical Technology

-ZM YB6315

P

Automotive

Energy Management

General Engineering

All

General Turning

Turning Inserts

Turning Tools

Parting Off and Grooving Inserts

Thread Inserts

contact

ZCC Cutting Tools Europe