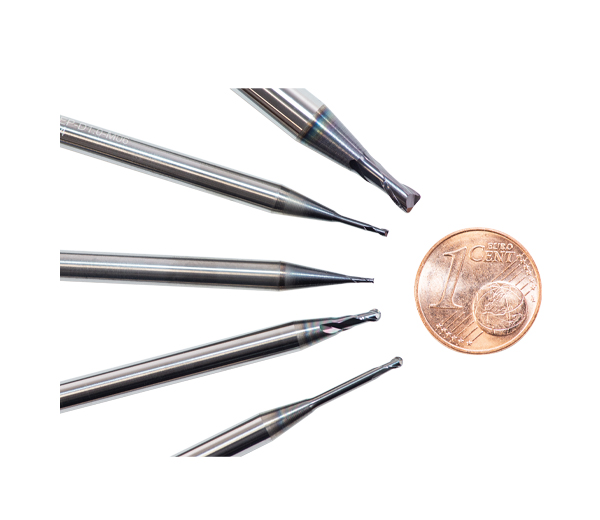

You can find a wide assortment of solid carbide cutters in our catalog. From micro-tools to HPC cutters, we have the right tool for practically every application. In combination with our regrinding service, we make your production more sustainable and efficient.

Solid Carbide Cutters

Recommendations for Solid Carbide Cutters

Overview of Solid Carbide Cutters

XM-2C series

K

M

P

Automotive

Die and Mold Making

Energy Management

General Engineering

VPM series

K

P

Automotive

Die and Mold Making

General Engineering

UMC Series

K

M

P

Automotive

Die and Mold Making

General Engineering

Rail Technology

CP-EM Series

X

Aerospace

Automotive

Computer/Communication/Consumer Electronics

FM Series

H

K

M

N

P

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Medical Technology

Q-HMX Series

H

Die and Mold Making

General Engineering

Q-PM Series

K

M

P

Automotive

Die and Mold Making

General Engineering

PM Series

H

K

M

P

Die and Mold Making

General Engineering

PM Micro Series

H

K

M

P

Automotive

Computer/Communication/Consumer Electronics

Die and Mold Making

Medical Technology

ALP + ALG Series

N

Aerospace

Die and Mold Making

Energy Management

General Engineering

EPM Series

K

P

General Engineering

HM Series

H

Automotive

Die and Mold Making

General Engineering

HPC Series

K

M

P

Automotive

Die and Mold Making

General Engineering

NM Series

N

Energy Management

General Engineering

TM Series

M

S

Aerospace

Energy Management

Medical Technology

UM Series

K

M

P

Die and Mold Making

General Engineering

Medical Technology

VSM Series

M

S

Aerospace

Energy Management

Medical Technology

PGMS series

M

S

Aerospace

Energy Management

Medical Technology

All

Chamfer Mills

HPC Trochoidal Mills

Square Shoulder Mills

Copy Mills

contact

ZCC Cutting Tools Europe