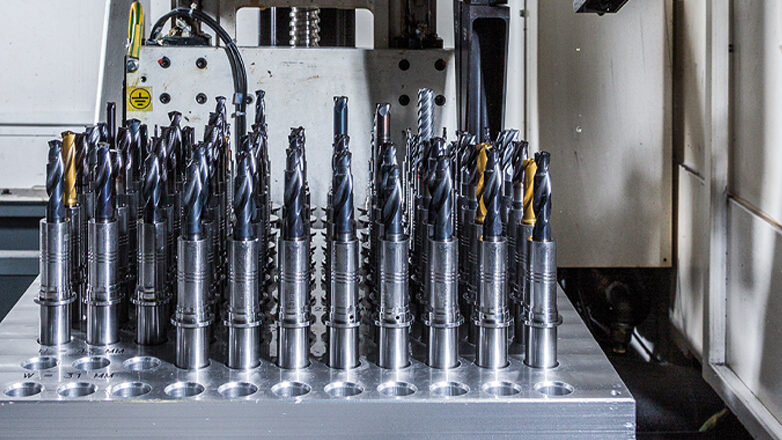

In most cases, solid carbide tools can be reground multiple times. Whether and, above all else, how often this should be done from a cost perspective is something we assess in each case before regrinding a tool. Once we have done this, we consult with you and decide on how to proceed. The tools are given their original finish, ensuring you get the full performance and tool life for your production operations. This significantly reduces your machining costs, helps you lower the amount of raw materials you use and further reduces your carbon footprint.

We also improve the cycle times for regrinding processes on an individual, case-by-case basis in consultation with you. This means you need to stock fewer tools and can therefore reduce the amount of capital you have tie-up in tools and the costs that go with this.

We work with our partner WEMA to provide you with a non-binding, personalised quotation in advance, taking into account all the parameters and specifications relating to your requirements.