In addition to turning tools, milling cutters, and drills, we also offer further options to upgrade your processes, ranging from intuitive torque wrenches to our modular spindle system. We are sure to have the right solution for you.

Tooling Systems and Related Equipment

Recommendations for Multi-Purpose Systems

Overview of Tooling Systems and Related Equipment

zFlex modular grooving system (cut-off)

M

P

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Medical Technology

Rail Technology

zFlex modular grooving system (grooving/turning)

M

P

S

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Medical Technology

Rail Technology

Simply Torque MASTER KIT

Spindle system

Cartridge

Digital display unit

Tool holders

Aerospace

Automotive

Die and Mold Making

Energy Management

General Engineering

Medical Technology

Rail Technology

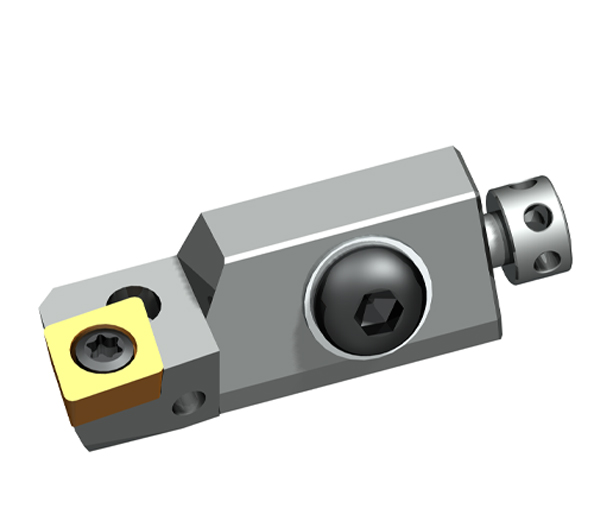

miniTURN

M

P

S

Aerospace

Automotive

Computer/Communication/Consumer Electronics

Die and Mold Making

Energy Management

General Engineering

Medical Technology

zRay High-pressure tool

M

P

S

Aerospace

Automotive

Energy Management

All

Parting Off and Grooving Tool Holders

Tooling Systems and Related Equipment

Turning Tools

General Turning

contact

ZCC Cutting Tools Europe